Layer Cage

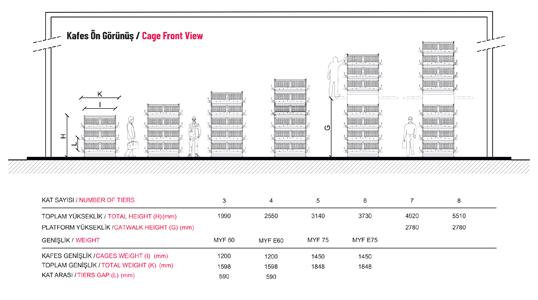

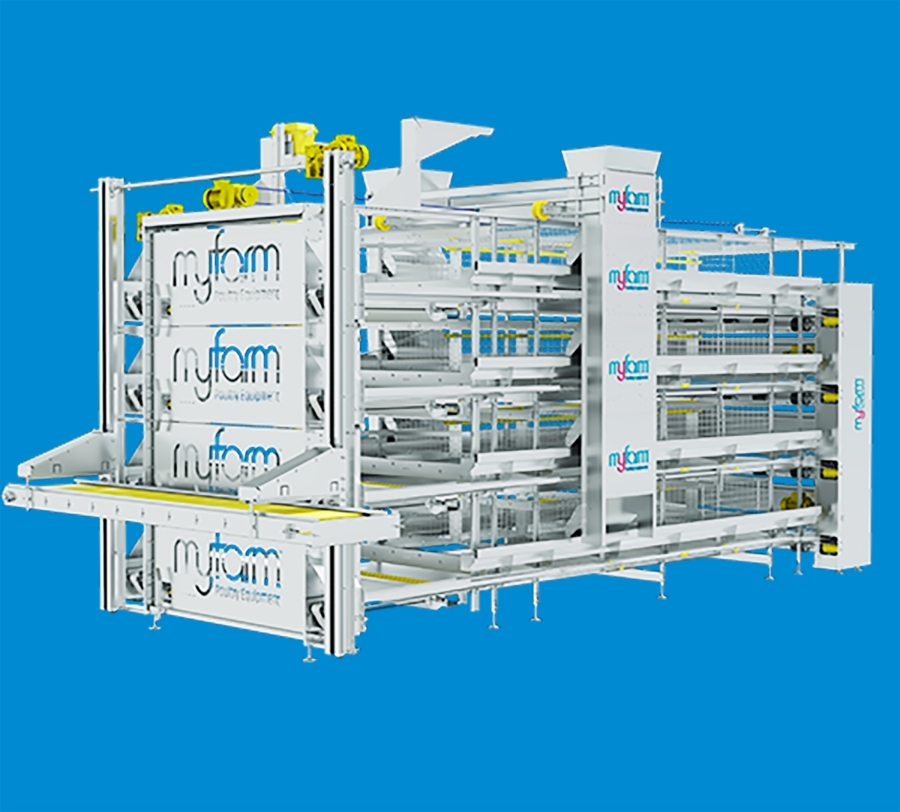

As MyFarm, we produce laying hen cage systems based on customer preferences and needs that change with the evolution of technology. Our expert staff performs R&D studies to maximize efficiency. We work in a customer-oriented way for the production of our models. Our standard products, the Myf-60 and Myf-75 model systems, as well as the MYF - E60 and MYF - E75 model cage systems, we have layer cage systems in two different models and in 4 different sizes. However, in the models of layer cages, we provide different optional choices for the customer besides the standard production. Every part of our MyFarm Cage Systems is made from first class galvanized sheet metal and wire. Since we put quality first in the production of cage systems, we use galvanizing to make the cages rust-proof, mildew-proof and have a long service life. As a result of R&D studies, the most suitable galvanizing rate for the cage system has been determined and this galvanizing rate is used in our products. We work with suppliers who implement ISO 9001:2008 Quality Management System, ISO 14001:2004 Environmental Management System, OHSAS 18001:2007 Occupational Health and Safety in accordance with quality standards.

Why choose the MyFarm layer cage?

- -Specially designed cage cell sizes that provide comfortable movement space for hens.

- -Horizontal sliding covers that save time and effort.

- -Stainless nipples in a PVC pipe that allow hens easy access to water.

- -Feeding systems that distribute feed evenly, quickly and homogeneous through feeders.

- -Manure band made of polypropylene (plastic) which evacuates manure quickly and hygienically.

- -Eggs are collected sensitively and cleanly.